|

|

PDF BAS6960 Data sheet ( Hoja de datos )

| Número de pieza | BAS6960 | |

| Descripción | BRINKMANN-Screw Pump Operating Instructions | |

| Fabricantes | BRINKMANN PUMPS | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de BAS6960 (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

BAS6960

Operating Instructions

BRINKMANN-Screw Pump

BFS / TFS / FFS

BRINKMANN PUMPS, Inc.

47060 Cartier Drive

Wixom, MI 48393

USA

Phone: +1 248 926 9400

Fax.: +1 248 926 9405

Subject to change without prior notice.

Brinkmann Pumpen

Edition 03/2014

www.BrinkmannPumps.com

contact @BrinkmannPumps.de

Order - No.: BAS6960 ENGLISH

Page 1 of 12

1 page

3.8 Unauthorized alterations and production of

spare parts

Any modification may be made to the machine only

after consultation with the manufacturer. Using spare

parts and accessories authorized by the manufactur-

er is in the interest of safety. Use of other parts may

exempt the manufacturer from any liability.

4 Transport and storage

Protect the pump against damage when transport-

ing.

The pumps may only be transported in a horizontal

position and hooks or straps must be attached on the

motor and pump end.

Pumps must be drained prior to their storage.

Store pump in dry and protected areas and protect it

against penetration of foreign bodies.

Always store pump above the freezing point!

5 Installation / Connection

5.1 Mechanical installation

Installation

The pumps can be mounted either horizontally

(foot mounted inline version) or vertically (immer-

sion style) .

For safety reasons installations with "motor

facing down are not allowed".

Pumps must be mounted securely. Piping, tank

and pumps must be mounted without any tension.

The actual mounting of the pumps depends on

size, style and motor used and might be influen-

ced by actual limitations or restrictions on site. In

any case, the pumps must always be mounted

securely.

Piping

Follow the recommended piping installation

guide lines as well as the required tightening

torques.

Work carried out on high pressure screw

fittings, pipes and hoses should only be per-

formed by authorized specialists and must

consider the applicable standards and local

legislation.

Only use components which are rated for high

pressure (i.e. no brass)!

Do not use fluid sealant or adhesives near the

pump or the pressure relief valve (risk of bond-

ing).

Connect and disconnect the pressure line only

when pump and relief valve are de-energized.

Do not prop up the pressure line via the joining

socket.

Do not climb onto the pressure line.

Connect the suction line, pressure line and

positive pressure outflow line as shown in

drawing 1, see chapter 7.1.

Pressure

side

Pressure

limiting

valve

Pressure

relief pipe

Drawing 1

BAS6960

Edition 03/2014

35

max.

liquid level

min.

liquid level

H

Suction side

Page 5 of 12

5 Page

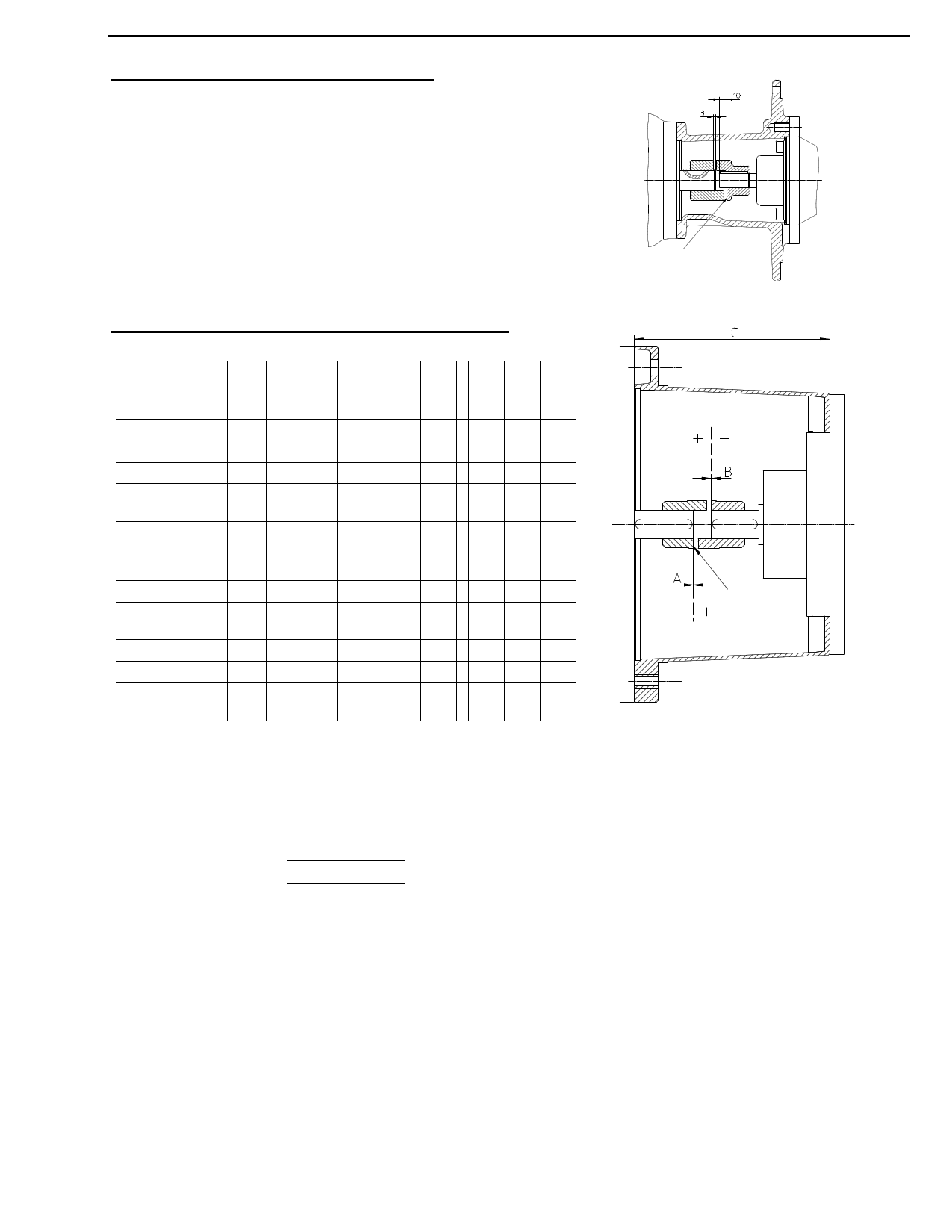

Dimensions for BFS1/BFS2 (2 pole motors):

In each case the distance is measured by the inner surface of the

coupling hub to the shaft end

Dimensions for TFS3, TFS4 and TFS5 (2 pole motors):

TFS3

TFS4

TFS5

Power

50 Hz / 60 Hz

HP

3.0 / 3.4

4.0 / 4.6

5.4 / 6.2

7.4-10 /

7.7-11.5

15.0-25.0 /

17.0-28.5

29.5 / 33.0

40.0 / 45.0

40.0-50.0 /

45.0-56.0

60.0 / 68.0

74.0 / 83.0

101-121 /

113-135

A BC

ABC

ABC

mm mm mm

-1 0 165

+4.6 0 183

+4.6 0 183

-2 -2 196

mm mm mm

-1.5 -1.5 170

0 0 183

0 0 183

0 +5 210

mm mm mm

+1 0 220

+7 +15 256 +7 +10 256 0 +3 256

+7 +13 256

0 +19 256

+7 +8 256

0 +15 256

0 +1 256

+1 0 256

0 +21 262

0 +7 262

+2 +6 295

-34 +30 295

Dim. A: Distance between inner surface of the coupling hub and the

motor shaft end

Dim. B: Distance between inner surface of the coupling hub and

pump shaft end

+ = Inner surface of the coupling hub is higher as shaft end

- = Inner surface of the coupling hub is lower as shaft end

ATTENTION

High axial impact loads on both pump and motor shafts during

the coupling assembly process are to be avoided at all costs

in order to prevent any damage to the pump and motor bea-

rings.

11.2 Repairs to the pump

In general, the pumps do not need servicing or maintenance and

only need to be sent to the manufacturer in order to be repaired.

Upon request, the manufacturer provides training and information

sheets on the subject of spindle sets.

12 Disposal

When disposing of the pump or the packaging materials the local

and national regulation for proper disposal must be complied with.

Prior to its disposal, the pump must be completely drained and

decontaminated if necessary .

BAS6960

Edition 03/2014

Inner surface of

the coupling hub

Inner surface

of the coupling

hub

Page 11 of 12

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet BAS6960.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| BAS6960 | BRINKMANN-Screw Pump Operating Instructions | BRINKMANN PUMPS |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |